advantages of hardness testing|hardness testing standards explained : companies In this article, we briefly explained the importance and application, advantages and disadvantages of Rockwell hardness test. We also introduce the Rockwell test with different indenter types, such as diamond cones and carbide balls. webO conteúdo da Trivela no Telegram, com textos sobre futebol internacional e nacional.

{plog:ftitle_list}

Resultado da Get all the latest news, live updates and content about the World from across the BBC.

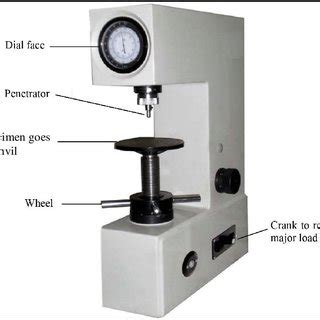

how hardness testing works

In this article, we briefly explained the importance and application, advantages and disadvantages of Rockwell hardness test. We also introduce the Rockwell test with different indenter types, such as diamond cones and carbide balls.

hardness testing standards explained

Micro hardness test is used for measuring the hardness of thin or small objects, . Micro hardness test is used for measuring the hardness of thin or small objects, complicated shapes, surface coatings, and plantings. This .

Advantages Of Rockwell Hardness Test. 1. Versatility and Wide Applicability. 2. Quick and Efficient. 3. Ease of Use. 4. Wide Range of Hardness Scales. 5. Surface Preparation Flexibility. 6. Non-Destructive Testing. 7. Adaptability to .The Rockwell method has the following advantages: no specimen preparation required (separation, grinding, embedding) hardness value directly readable, no optical evaluation required (measurement of diagonals as in the optical methods) Advantages of Rockwell Hardness Test. Typically, the Rockwell test is easy to execute and more precise than other kinds of hardness evaluations. The Rockwell test technique is used on all metals, except when .

The Rockwell method offers the following advantages: No specimen preparation required (cutting, grinding, embedding) Direct reading of the hardness value; no optical evaluation required (measurement of diagonals as with optical methods)

What is suitable when? If you need a quick, non-destructive measurement for a variety of materials in a manufacturing setting – the Rockwell hardness test is suitable. For softer materials or materials with coarse microstructures – the . This is due to a number of advantages as listed below. 1. No Material Preparation is Required. In some tests, the sample material has to be buffed, ground, cut up, and polished in order to get the most accurate of .

hardness testing meaning

hardness testing materials

torch lighter drop test

The Vickers hardness testing method offers advantages such as a small indentation size, accurate hardness measurements, and applicability to a wide range of materials. Series measurements or mappings are very often carried out using this met-hod. However, it may not be suitable for very soft or highly textured materials, while alternative .

Many manufacturers use portable hardness testers, which offer several other advantages. What is Hardness Testing? Hardness testing is used in mechanical and materials engineering to test the hardness of a .

The Vickers hardness test has the given advantages: The Vickers hardness test can measure the entire range of hardness values as it can evaluate all the materials and samples used for the test, whether they are soft or hard in texture. There is no complication in the type of testers as it has only one indenter used for every method of Vickers test.The Vickers hardness test is ideal for testing of all metals and is therefore the method with the widest range of application. The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 gf) of Materials .

The most common hardness tests that measure the relationship between hardness and the size of the impression left by the test are the Rockwell, Brinell, and Vickers hardness tests. Rockwell hardness tests are the most common type of hardness test available, and for good reason: it’s an incredibly fast and reliable method to determine the . The Rockwell hardness test involves making an indentation on the test material. The indenter is either a conical diamond or a steel ball. Indenter ball diameters range from 1/16 to 1/2 inches and are chosen based on the test parameters. .

These hardness tests can be categorized as macro and micro. All hardness testing methods lie under these categories. In this article, we will discuss hardness types, advantages, disadvantages, and applications. These things are important to understand as they have many consequences on the mechanism of indentation in the hardness testing methods.Applications of Rockwell Hardness Test. Quality Control: Commonly applied in industries that require hard materials on parts and other manufactured products. Material Selection: This tool supports the process of identifying materials that will be applicable depending on the hardness needed. Heat Treatment Evaluation: Using the assessment of the hardness of the treated .Advantages Of Rockwell Hardness Test 1. Versatility and Wide Applicability. One of the significant advantages of the Rockwell hardness test is its versatility and wide applicability across different materials. It can be used to measure the hardness of various metals, including ferrous and non-ferrous alloys. Additionally, the Rockwell hardness .

In the Brinell Hardness Testing, the hardness of a metal is determined by measuring the permanent indentation size produced by an indenter. . The Brinell Test method has many advantages: The hardness of rough samples can be measured which is difficult with other methods. Application of high test load (up to 3,000 Kg) is possible. Wide . Additional Benefits Of Hardness Testing . By conducting a hardness test, the results obtained can be used to predict and determine the extent whereby the tested material can perform under various conditions. For example, by measuring the hardness at various temperature and humidity conditions can simulate and allow you to know if the hardness .The Leeb method is a quick and portable hardness test method, which is determined by the ratio of rebound velocity to the impact velocity of a moving impact body. It is best applied to solid parts of the object for example casting and forgings. In the article, we include the advantages and disadvantages of Leeb method in details.

The Vickers hardness tester offers several advantages over other hardness testing methods, such as broad applicability to all materials, high accuracy, and others. Please check out below. 1. Broad Applicability to All Materials. Vickers hardness testing suits various materials, including metals, ceramics, and some polymers.The specific size, shape, and location requirements of the hardness test determine the use of the Vickers method. One of the key advantages of the Vickers Hardness test is its versatility, as it can be applied to a wide range of materials and properties. Vickers Macro Hardness testing standards we work with: BS EN ISO 6507-1:2018 (HV1, HV5, HV10)Advantages of Brinell Hardness Test. Simple setup and operation – The Brinell Hardness Test is easy to set up and use, making it accessible for various users without the need for extensive training.; Wide material applicability – It works .

The Knoop method has the following advantages. The Knoop method can be used with any and all materials and test specimens, from soft to hard, as the procedure covers the entire hardness range. There is only one type of indenter, which can be used for all Knoop methods.

Advantages Of Rockwell Hardness Test 1. Versatility and Wide Applicability. One of the significant advantages of the Rockwell hardness test is its versatility and wide applicability across different materials. It can be used to measure the .

Advantages of Brinell Hardness Testing . Brinell hardness tests offer a variety of advantages that make them a preferred choice. 1. Adaptability to Testing Different Materials. One of the key advantages of the Brinell hardness test is its ability to test a broad range of materials. It is applicable to metals, alloys, and even some non-metals.Advantages of Brinell Hardness Test: Suitable for rough or irregular surfaces: The spherical indenter used in the Brinell hardness test can accommodate variations in the surface of the material being tested. This makes it suitable for testing materials with rough or irregular surfaces.

Enjoy the benefits of Rockwell hardness testing and the unprecedented accuracy it provides. In Conclusion. Despite its advantages, the Rockwell method is not exactly applicable at all instances. However, it does not mean that a Rockwell Hardness Tester will not yield considerably accurate measurements which should help any workshop. Advantages and disadvantages. The advantage of Rockwell hardness testing is the relatively short testing time and good automation capability, as the measured values are determined directly from the indentation depth without optical measurement under a microscope. This process is therefore particularly suitable for automated production.The Vickers hardness test is suitable for a wide range of applications, including micro hardness testing. On this page, you can find a description of the Vickers hardness test, practical information on how to apply it and a list of our micro hardness testing machines for Vickers. The Vickers hardness test at a glance: Ideal for micro hardness .

Hardness testing is a mechanical test that measures a material's resistance to indentation, scratching, or abrasion. There are several types of hardness tests. . Advantages and disadvantages of Biogas; Advantages, disadvantages & application of geothermal energy; Magma Geothermal Energy Source;Conclusion. Brinell and Rockwell hardness tests are valuable methods for evaluating material hardness, each with its own advantages and considerations.While the Rockwell test offers simplicity and faster results, the Brinell test is often favored for its perceived accuracy and reliability, particularly with coarse materials. The quotient of the test force divided by the surface area of the indentation is the Vickers hardness number. Vickers hardness value calculation formula: HV=constant × Test force/indentation surface area, where HV is the Vickers hardness symbol, F is the test force (in N), and d is the arithmetic mean of the two diagonal lines d1 and d2 of the indentation (in mm). A Digital Hardness Tester is a measuring instrument used to determine the hardness of a given material. It is an essential tool in industries where metals and alloys are produced or used. This includes a variety of industries including auto manufacturing, aerospace, oil and gas, and many others. Testing the hardness of metal including steel or composite .

What are the advantages of hard materials? Hard materials resist deformation, indentation or scratches making them harder wearing, longer lasting and often easier to clean and maintain. . The Leeb hardness test is commonly used for on-site hardness measurements, especially in large and heavy components, where other conventional hardness tests .

hardness testing instrument

hardness testing

Monday 12 Tuesday 13. Mon Feb. 12 16:30. Poker #8 - NLH - LOW SERIES by CasinoBarcelona.es - SUPER Mystery Bounty - Dia 2. Sunday 11. Mon Feb. 12 20:00. Poker #9 - NLH/PLO - LOW SERIES by CasinoBarcelona.es - Mixed Games - 1B (PLO Omaha) Monday 12 Tuesday 13.

advantages of hardness testing|hardness testing standards explained